Well System Components: Check Valves

Check valves are needed to keep the pump from running constantly. If a check valve is not installed, the water in the water service drops back into the well when the pump stops running. This will trigger the pump to run again. This will be an continuous cycle because the system keeps losing pressure. In this case a pump can be worn out very fast.

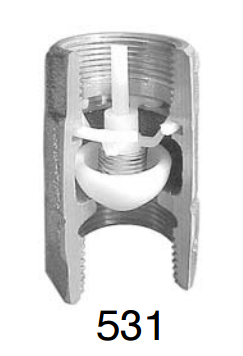

In the case of a jet pump, the foot valve acts as a check valve. When installing a submersible pump, the check valve is a brass fitting that is installed in-line in the piping to the pressure tank. Make sure you don’t install these valve backwards. If you do, no water comes to the tank. There is an arrow cast into the side of the valve that shows the proper direction for installing the valve. Install the check valve so that the arrow is pointing toward the pressure tank. Water will pass through the check valve easily in the direction of the arrow. When the pump stops running, pressure is off of the check valve and the check valve closes quickly. When the valve closes it will hold the water in place. This is a simple and inexpensive component, but critical to a well system.

Customers looking for quality check valves at at discount prices can check out our large selection here.